I was hooked by the looks of this unusual ship initially and then more and more of its history as I dug deeper… I first came across it as a ‘new release’ posting on the website of a paper model supplier and then ended up coming back again and again. Not exactly an Aircraft carrier as such, but a sort of ‘half-way-house’, an anachronism in itself. Either a white elephant or a black sheep – or both?? Well, I just had to have it! So here I am, a couple of months later with offerings of two publishers, one from Poland, GPM and the other from Belarus, Black Cat. The one from Black Cat has more detail (if you can decipher or even see it, due to the sometimes atrocious print definition) against the crisp print of the GPM model, which is very nice but in some areas very simplified – and in others better than the ‘competition’. Both were released at about the same time, which is curious.

I now have more time on my hands (theoretically) due to a bout of COVID which lasted three days, but which has caused untold damage to my internals… I have not been working since Christmas past (TIG-welding when wearing a defib is not a good idea!) and have been lined up for an internal pacemaker and defibrillator in the middle of July. Fingers crossed on that one and after that will be forced to enjoy my retirement…

Back to the Albatross and the models! Starting with my impressions of the Black Cat version, which I received first, the cover is what caught my attention initially. It depicts a fine photograph of HMAS Albatross soon after launching in 1928. Red below the waterline and pale grey livery (507c?) overall above except buff (‘yellow’) upper works and funnel as typical of the era in Australia, but the colours are difficult to definitively say in B&W anyway, as their depiction depends on so many factors…

Enough to say, that the picture itself is completely wrong, since the model is obviously supposed to be of the HMS (NOT the HMAS) Albatross in 1942 – so after the addition of various extra armament and (replacement of) the catapult on the aircraft deck and the fact that it is depicted with wartime camouflage – of which there are very few photographs and all unfortunately of awful quality…

There are hundreds of templates for extra detail (which means that a lot of detail is ‘missing’ on the paper printout) and has to be added by the modeller (mostly with wire, by the way automatically considerably improving detail and enhancing the overall impression once finished – one would hope!

The brass etched detail pack on thin foil is excellent and very fine in quality, showing a reasonable selection of necessary parts (some replacing the depicted templates, but omitting detail that would have been welcomed – like the supports for sunshades around the perimeter of decks attached to the railings and the cranes and catapult, which would have greatly benefitted from attention here. That, unfortunately is something that is often the case and I wonder sometimes what drives the choices of parts in publishers detail sets, when such obvious things are simply ignored that would greatly enhance build quality and save a lot of time, effort and frustration.

There are a number of inaccuracies on the flight deck in both models. in this one, the catapult is too far forward and in the GPM one, the hatch is too far aft. Interestingly in both renditions, it is assumed that there is a lifter the aircraft, but that is definitely not the case. As confirmation of this, it can clearly be seen that the hatch had a wooden framework proud of the deck, which would be idiotic if there was a lift – it would be impossible to roll the aircraft onto the deck with such a step. No, the aircraft were always hoisted from the deck below by one of the cranes, as depicted in many photographs of the period:

This is a Seagull Mk III being hoisted in or out (the prop is clearly at the front of the wing)… The fire curtains and the frame are clearly visible here, as is the fact that the frame is proud of the deck surface. The hatch was covered with a tarp arrangement when not in use.

Here is a shot of the skeleton of the ship before covering and a 1:200 reduction of the admiralty blueprint of the ship as fitted (including the catapult which was fitted later. I opened the Hangar deck bays 3 and 2, leaving the forward bay 1 closed, as it will anyway not be visible through the hatch after the deck in on. Details to be added just aft of the entrance to bay 1 are the towers for the munitions lifts/feeding systems for the QF 4.7 inch MkVII anti-aircraft guns on the deck above and the towers for the two aft cranes on the flight deck which reach don to the base of the hangar deck, which could probably be seen after the build.

Placed in the hangar deck you can just see the Seagull Mk V (later Walrus) to show how little space there is below dec for the aircraft, which was too tall to manoeuvre in the space, so they had to be moved on specially constructed trollies with their undercarriage retracted. The wing stays are a mite too long on this prototype (and will be modified accordingly on the next ones!) :

Here from a different angle showing the general layout below deck so far. Only one side has been rigged in these pics, hence the ‘slight’ twist in the upper wing…:

I made the prototype A/C, not from the Black Cat offering, which is atrociously printed in completely wrong colours, with extreme loss of visible detail.

The MkIII was even worse… Nice was the thought of providing three of each, but the designers efforts were completely thwarted by the print, even if the colours are wrong. (The MkV would have been allover silver and the MkIII had a brown painted wooden fuselage and silver wings…) Notice in particular the clarity of detail regarding the openings for the gunner/observer aft of the wings and for the pilot at the front, not to mention the proportions of the roundels etc. Here the ‘detail’ of the Seagull:

My prototype MkV was built from a ‘Scissors and Planes’ Walrus, reduced to 1:200, printed on card which was then sprayed on the ‘back’ with silver from a can, cut out and used with the silver side up, so to speak. Markings were provisionally adde by hand, as nothing from my printer sticks to silver paint – I’ll have to find a workaround for that. Rigging is a horror-trip, done with elastic rigging obtained from ‘Uschi Glas’ on the internet. Prop and undercarriage also missing in these shots.

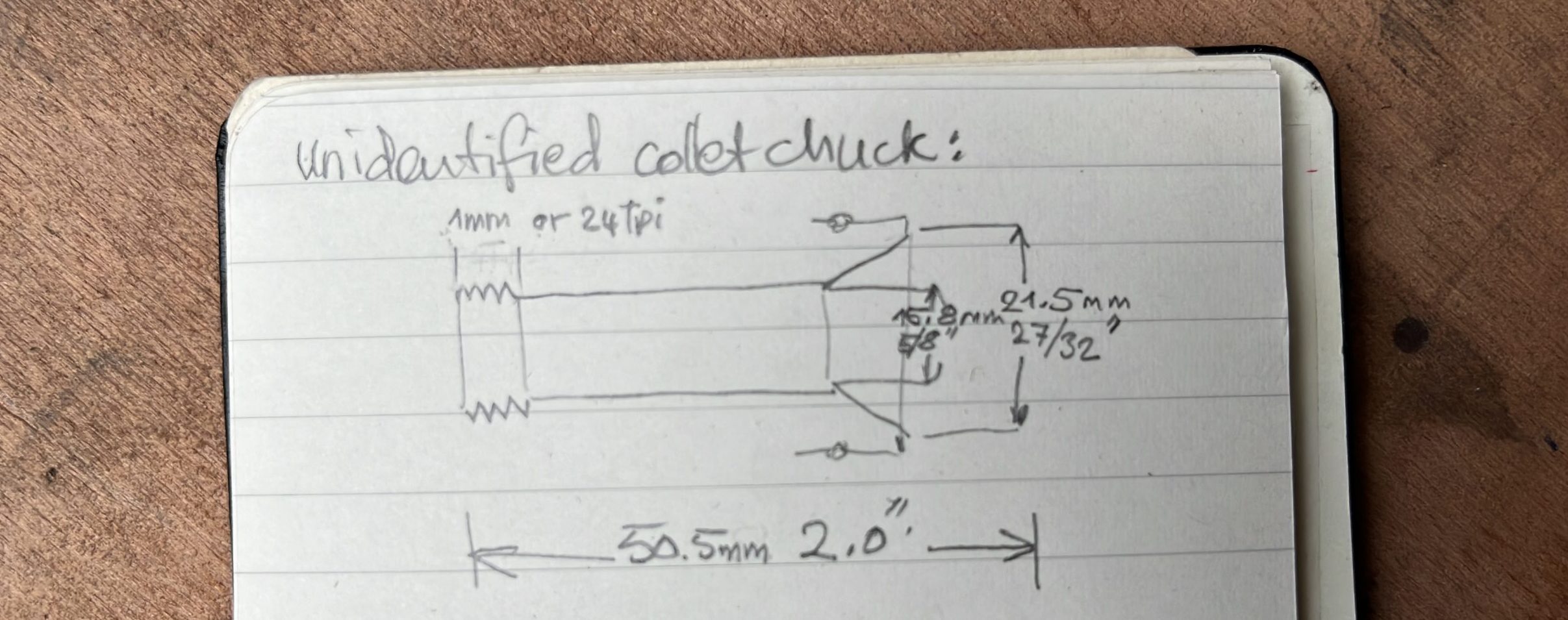

Here are the dimensions:

Here are the dimensions:

Maybe at a later date I will even post a sound sample, who knows!

Maybe at a later date I will even post a sound sample, who knows!