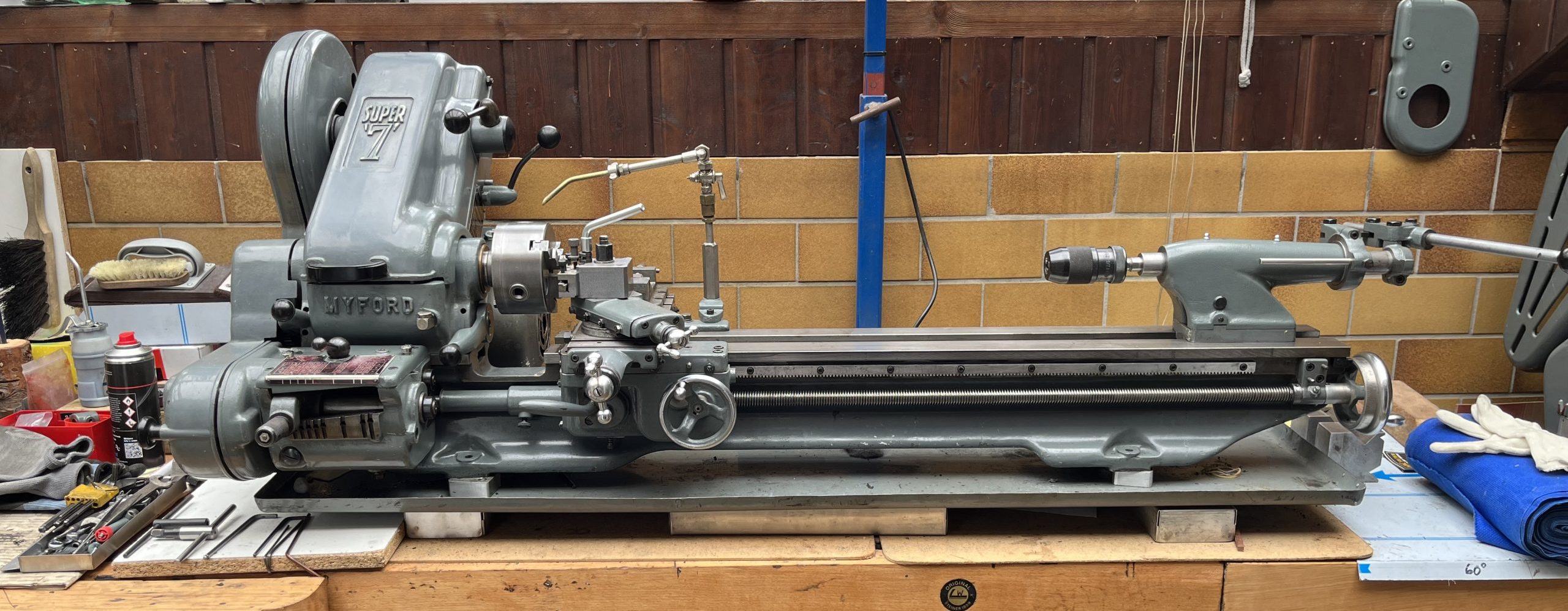

Well, as it states above, I couldn’t help myself… I bought another, later version (around ’65) Super7 in super condition with loads of accessories for a very reasonable price. It included everything needed to run a 400V motor on 240V without losing power or any of the other advantages of the 400V system. Also in the deal was a manual Capstan setup including six tool posts and the separate stop-system which belongs to it. Also a Norton gearbox including the metric thread conversion kit all boxed up. That alone was covered by the purchase price, so I was very happy!

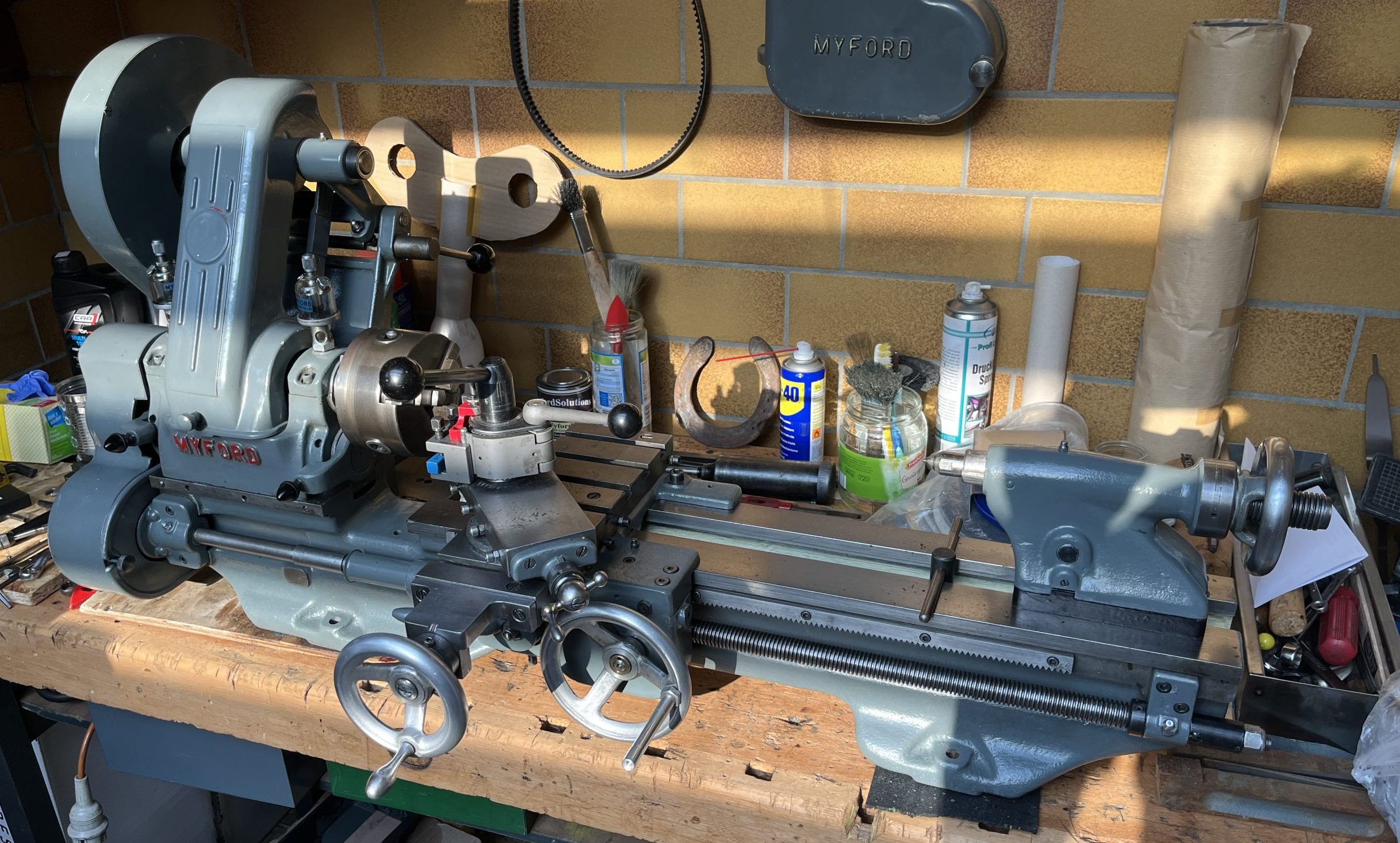

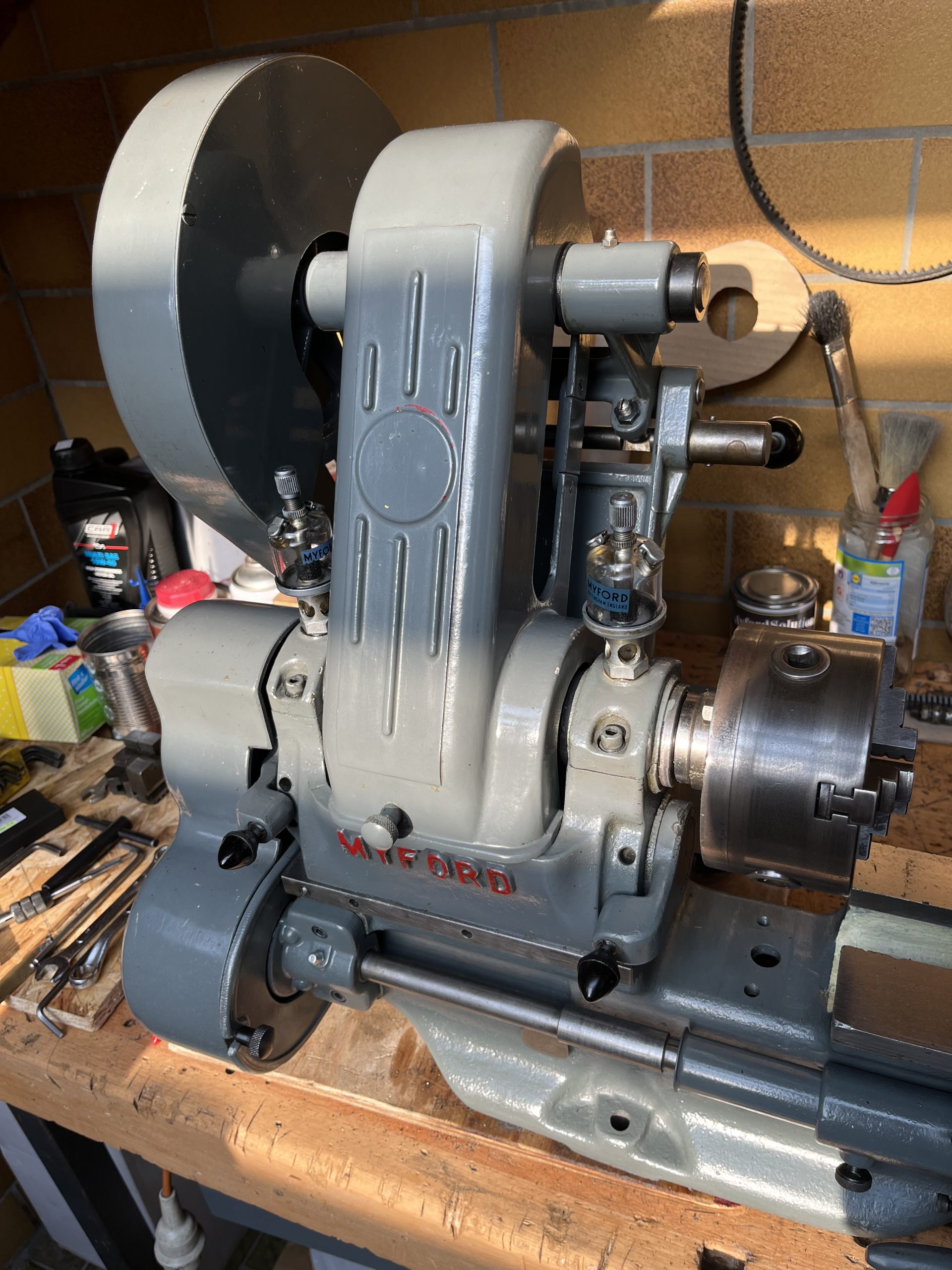

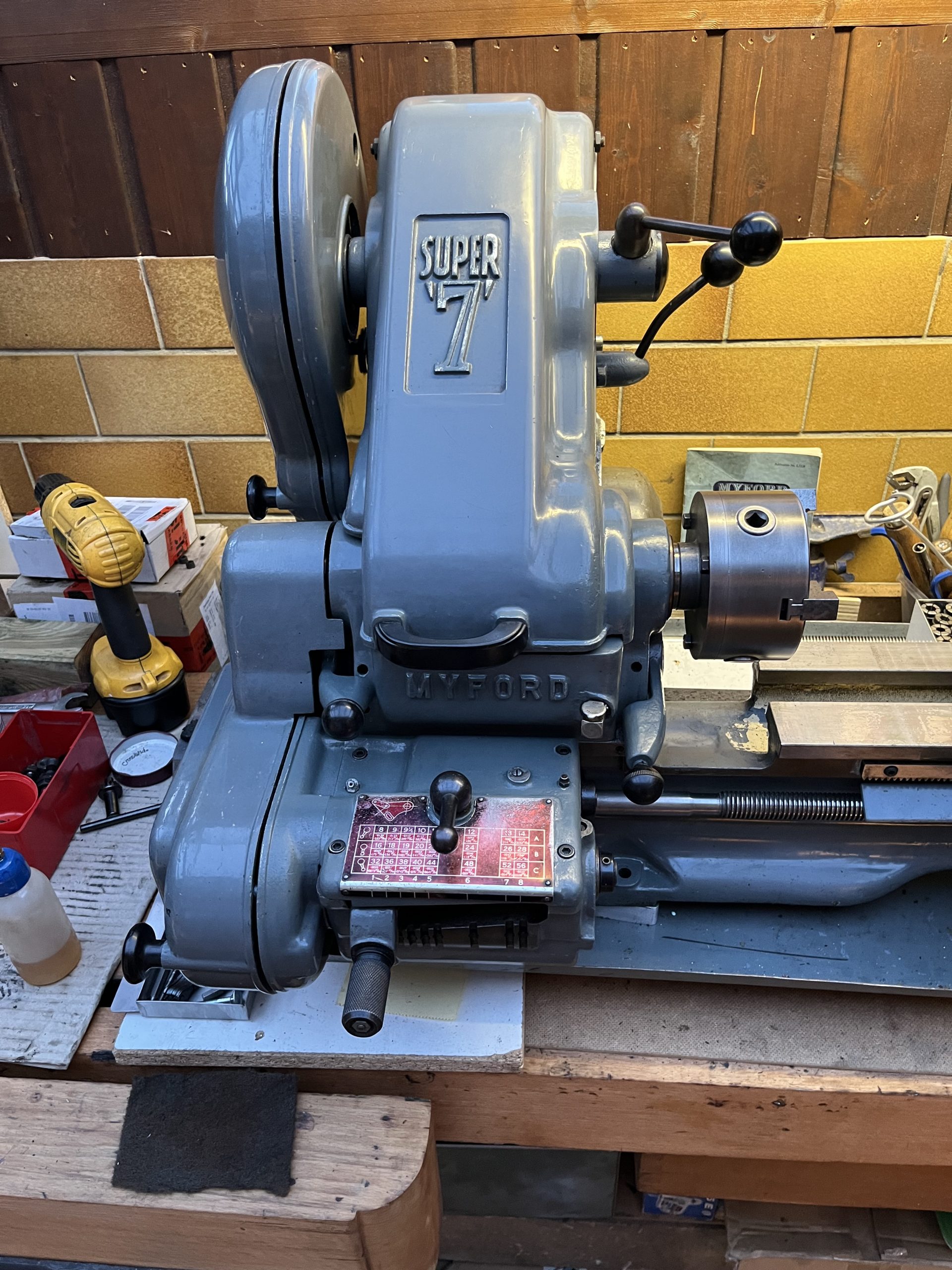

The longed Super7 above is the fruit of my labours. it has a 400V motor running through an inverter from 240V -very smooth power-delivery and due to the three-phase, much smoother cuts as well! (240V motors ‘stutter’, due to the missing phase and so the cut is not as smooth). I had to cut the end off the main spindle, of course, to fit in the gearbox. I shall get a new, full-length, spindle, so that I can remove the box and refit the standard setup, in case I have to cut threads outside of the box’s scope, like BA and CEI. I have all the covers etc to convert back to original, of course.

I have a Myford vice and nearly all the possible gearwheels and some-such which I shan’t bother to photograph, plus the odd faceplate, too and a turning tool-rest.

Once I have everything mounted on its pedestal and is up and running, I’ll post it here…

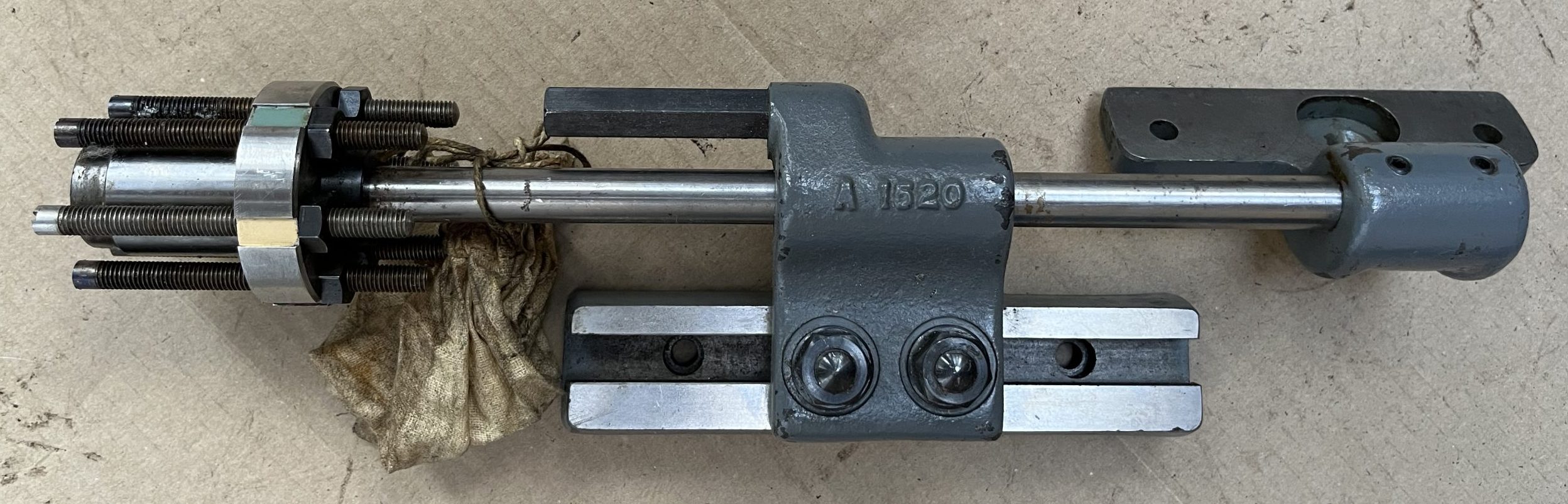

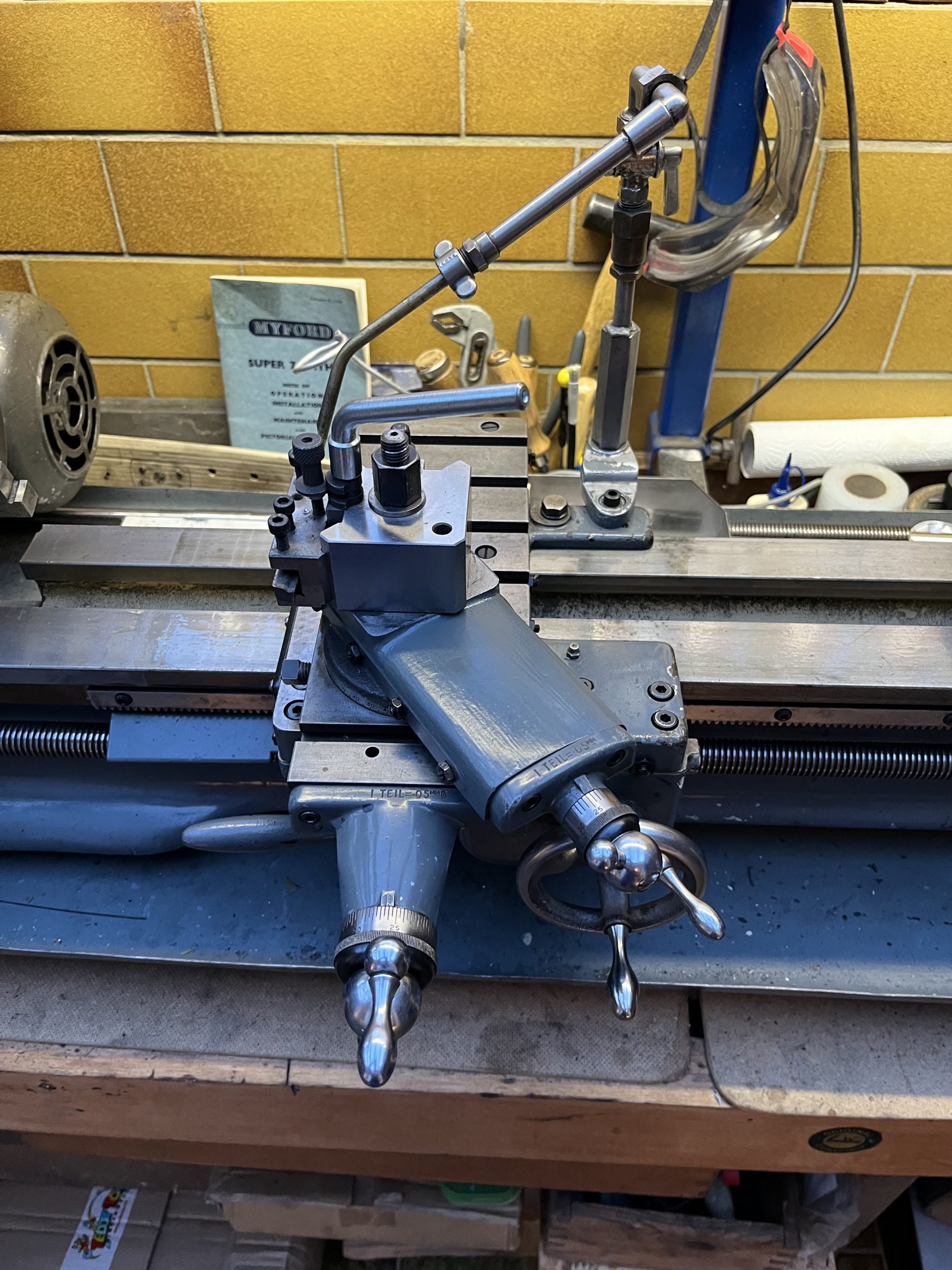

So here a few of the goodies I acquired: The manual capstan head and a full set of tools:

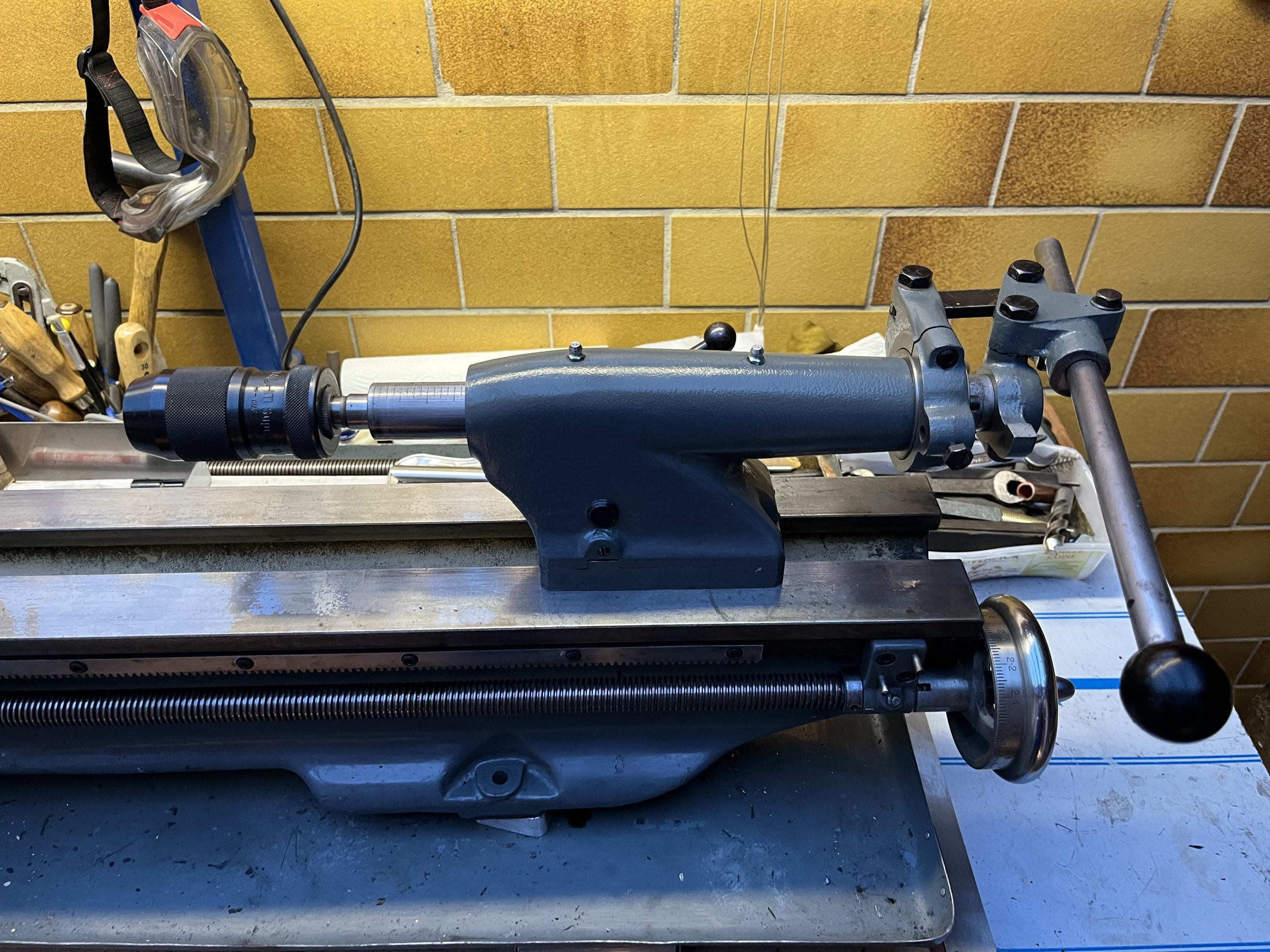

This is the stop-setup for the above unit:

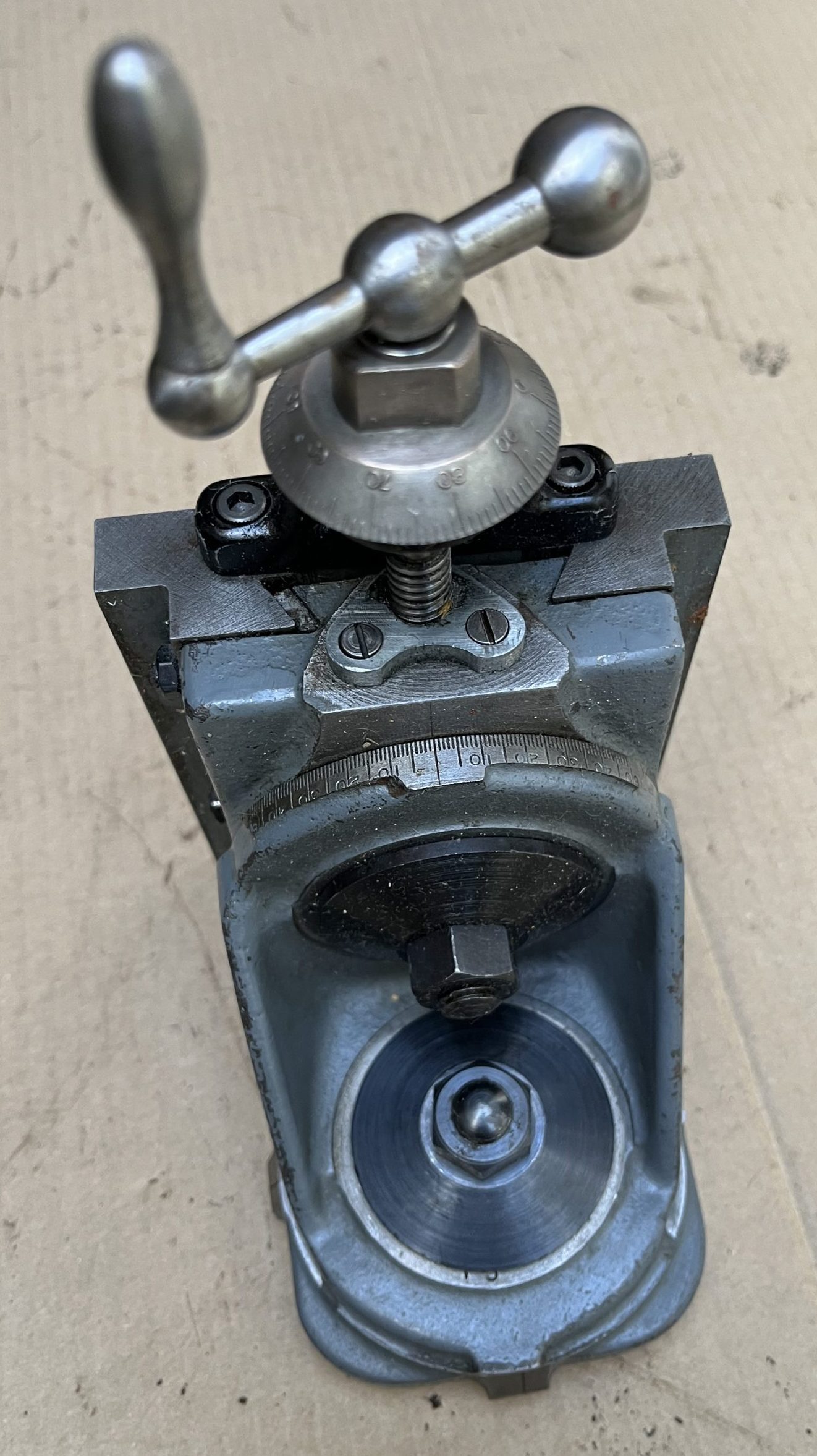

Vertical slide, swivelling type:

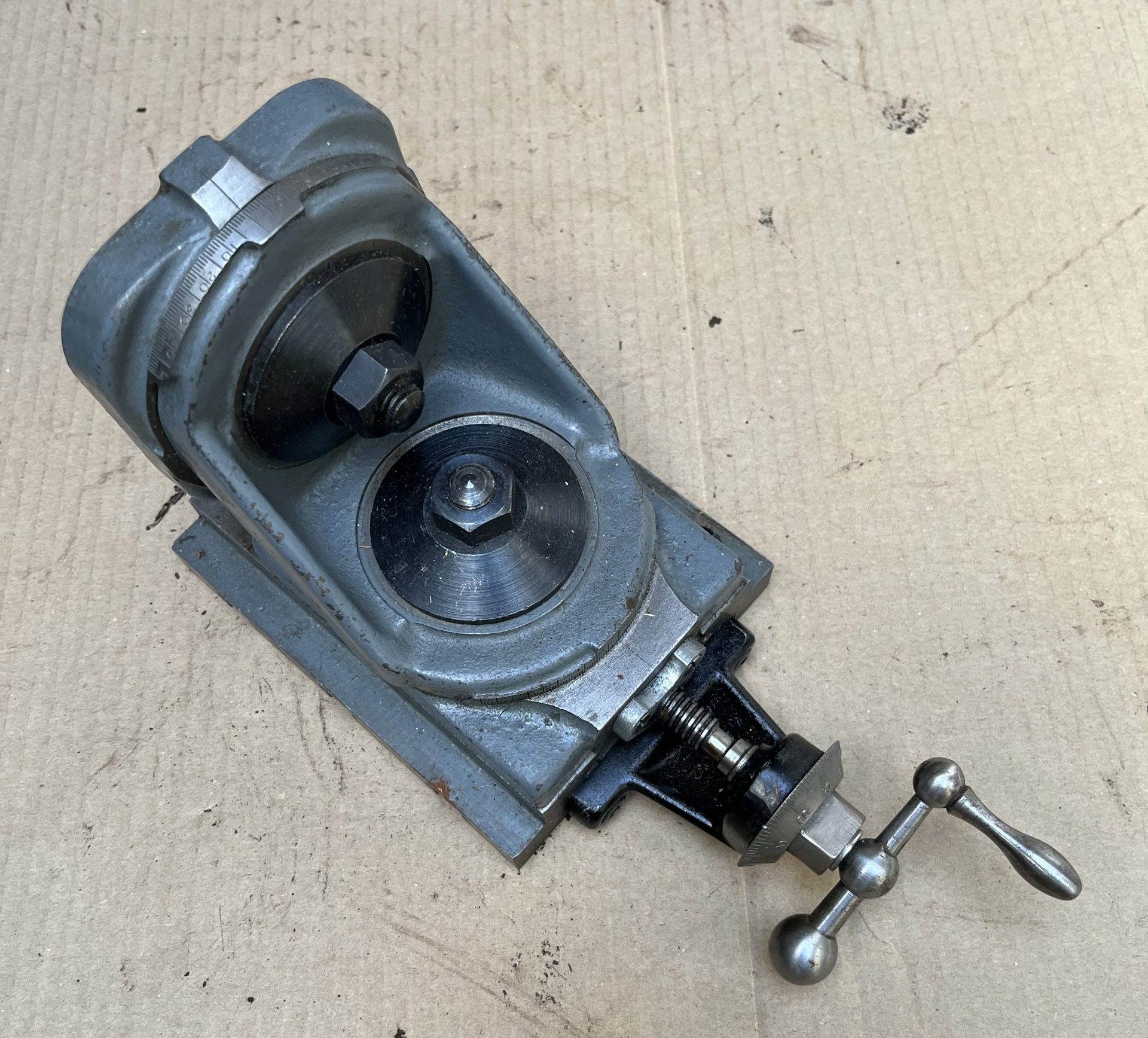

The mystery lever-operated collet attachment, for which I haven’t yet been able to find any collets on the internet…(still needs cleaning up!)

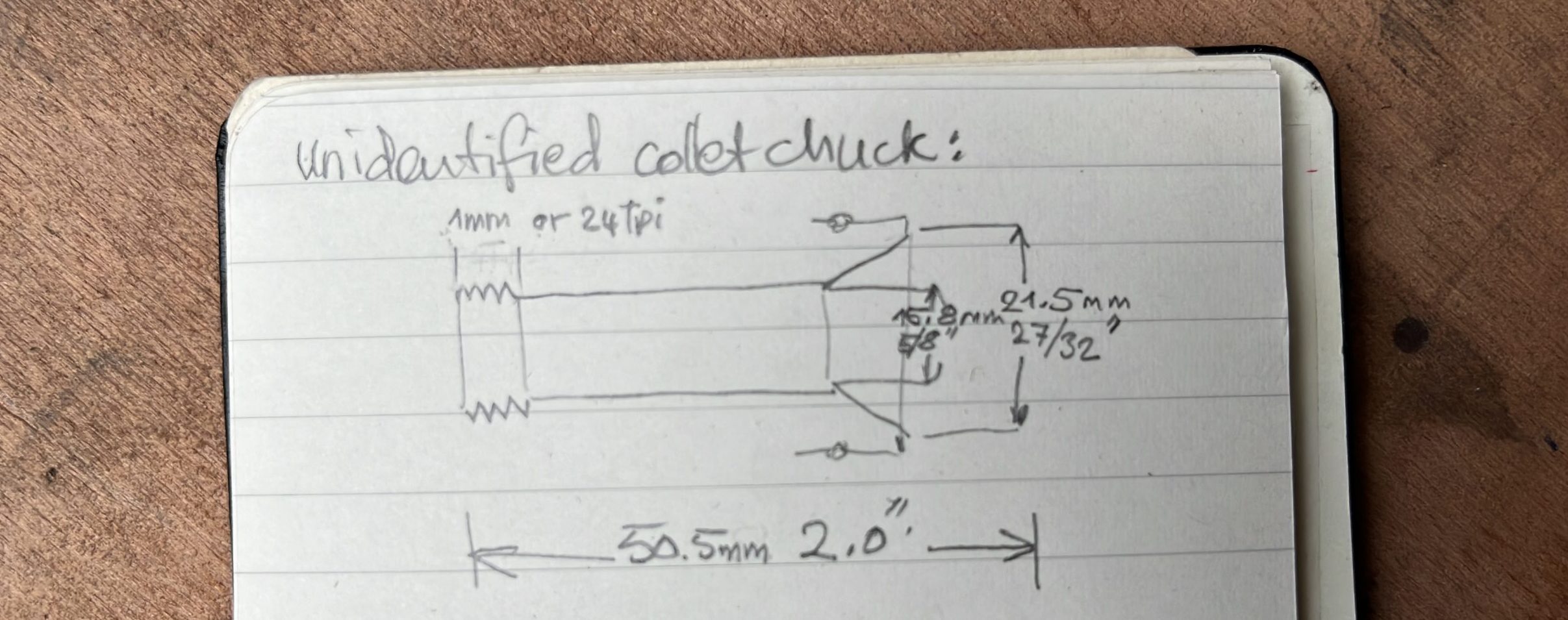

Here are the dimensions:

Here are the dimensions:

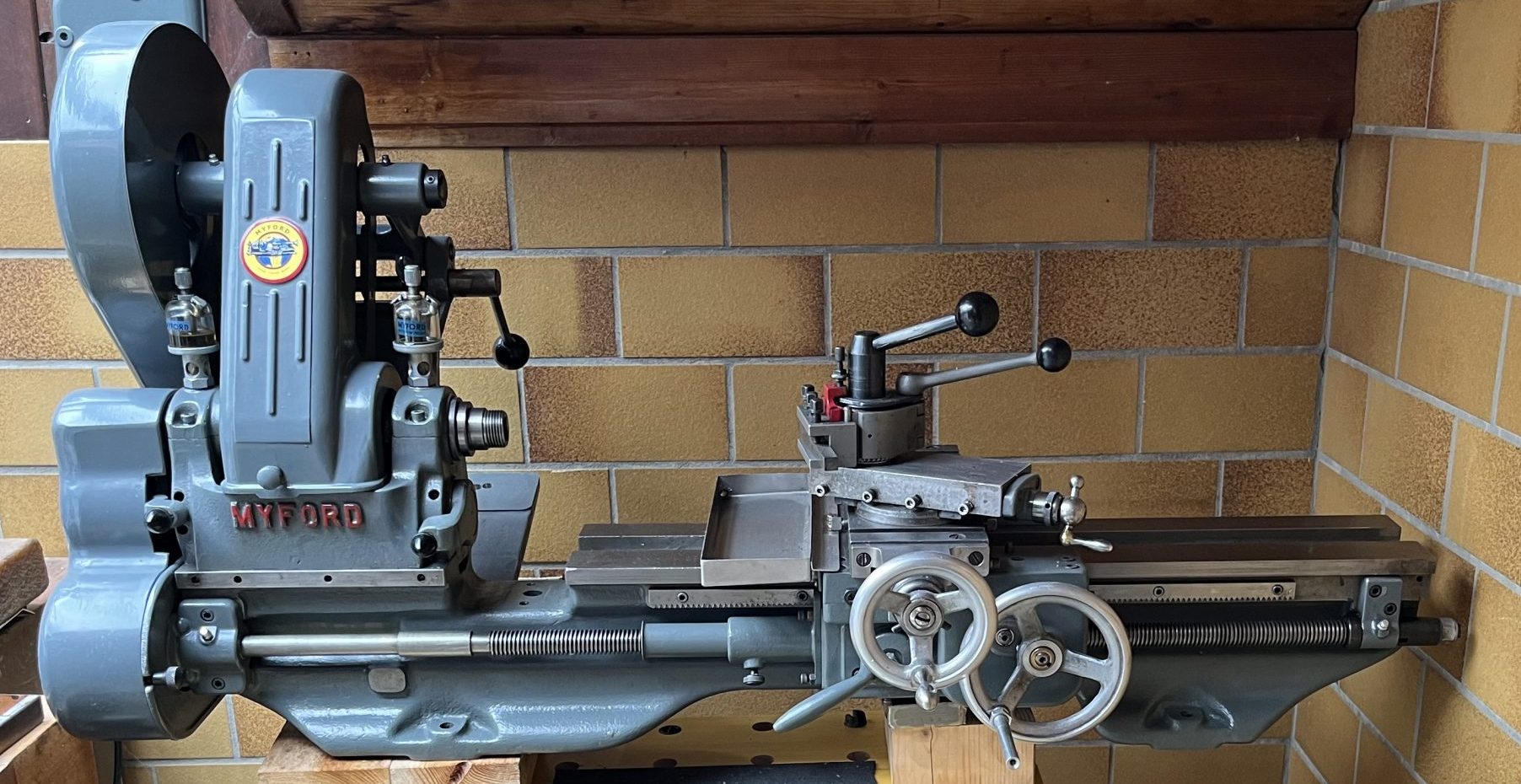

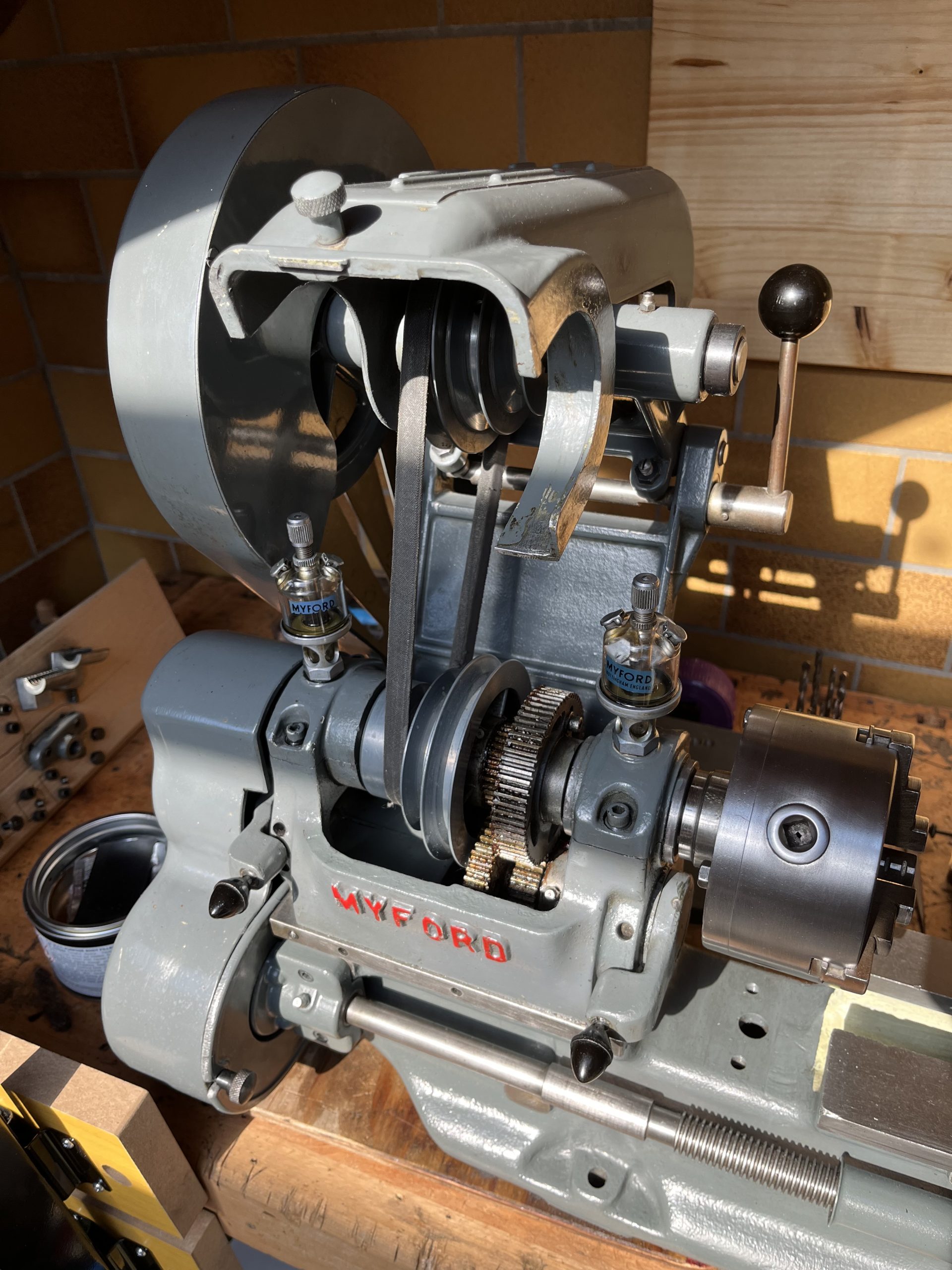

This is what the standard-bed 1959 ML7 now looks like (minus the belt-cover transfer, which is now on it!)

Now standing in the corner minus chuck, headstock and motor (stored underneath the bench!)

Now standing in the corner minus chuck, headstock and motor (stored underneath the bench!)

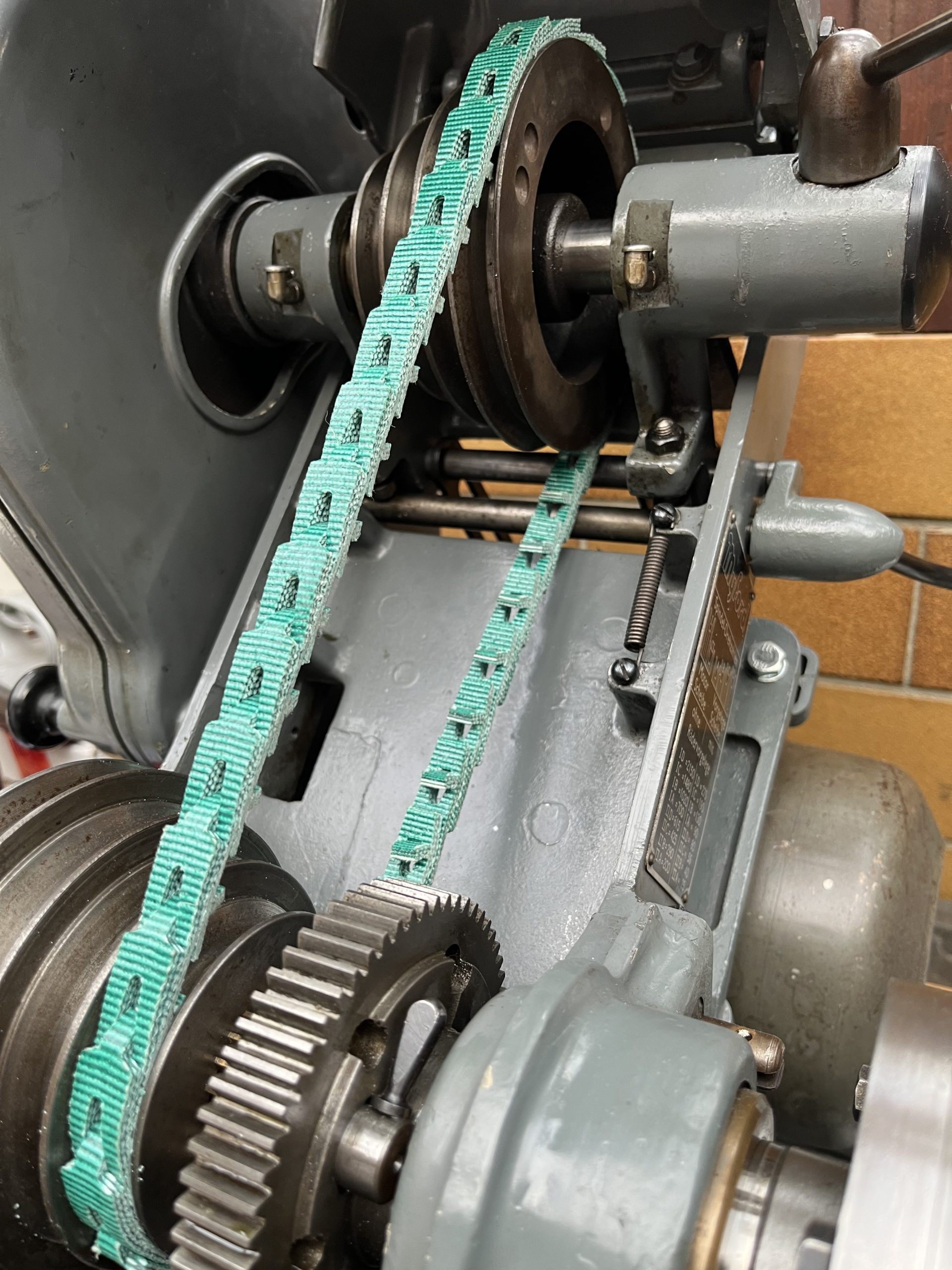

So now back to the long-bed again: The new drive belt. Now I can split the clutch from the drive unit without dismantling everything “above the waist” and it is grippier, too!

The ‘new’ Gearbox with the original panel (not the new ones available now, which are subtly different…)

Coolant-feed (The actual feed and box is still not made…)

My nice lever and chuck for the tailstock!:)

So now you have a good idea of the swapping and changing that went on, as the long-bed was originally an ML7 and the standard bed was fitted with a Super7. The first super& needed lots of work and cleaning to bring up to standard. The bed was reground and now sits under the ML7 pictured above and some of the other parts, too. The second Super7 was in much better condition and most of those bits ended up on the Long-bed also pictured above.

A mix of parts, including most of the first one (1960, so Mk1) which I had done considerable work on (covers, saddle, cross slide, tailstock etc.) and the really good bed still in original paint, are up for grabs as a complete machine or in bits. The internals of the motorising assembly and headstock from the first one are pretty filthy and I didn’t have ago at that yet, but being Super7, all in good working condition (the main bearing being an adjustable taper!) We’ll see!